The Truth about Thermal Insulation

Hot always goes to cold unless energy is used. It cannot be stopped, only slowed down. So those companies who claim they can stop heat loss are kidding you.

Heat is the product of atomic / molecular collisions. Similar to your hands becoming warmer if you rub your them together for a short period. (there are other forms of heat such as chemical reaction - it is still atoms moving)

In solid items the molecules cannot move much other than vibrate therefore requires a lot of energy to keep the vibrations going. That is why it takes a lot of energy to heat dense materials such as metal, masonry and glass. (Technically glass is a super cooled liquid as opposed to a solid).

Materials that are made up of thin membranes with voids between them have a mixture of solids and gases. Timber is a good example. Softwood has millions of very small tubes termed trachieds. The walls of the trachieds are very thin cellulose.

When the wood has dried out to become timber the liquid content is significantly reduced and replaced with air. The air is trapped inside the tracheid and has very few molecules. The ratio of cellulose wall to void is important.

As the tree is growing the tracheids will be full of liquid either containing water and minerals going up to the leaves, or sap with a very high sugar content coming down after photosynthesis has taken place.

Due to the cellulose walls being very thin the amount of thermal energy required is small. There are not many molecules to move and the vibrations take longer to slow down. Thermal insulation qualities of timber are very good, especially softwoods. Not all though. The density of European Redwood (typically used to make softwood window frames) is about twice that of extruded PVCu. The former being about 510kg/m3 compared with about 240kg/m3.

However, it isn’t an easy comparison. The heat transfer through the material is dependent on how much connection there is between the components.

A dense material can transfer heat easily by conduction but if there isn’t much of it and it isn’t continuous, then it can be a good insulation. That is why fibre glass loft insulation is a good insulator. The main component is glass which conducts heat easily.

If the glass is formed into fine fibres it would easily fall apart therefore the manufacturers extrude thousands of fibres from one angle and then thousands at right angles forming a mat like layer each time. The layers build up to form the thickness of the insulation.

Not all fibre glass / mineral wool is formed in the same way.

One method of manufacture developed by Pilkington Brothers is to produce thousands of layers of glass rods (fibres) as a mat. The layers are fired at right angles so that one set of fibres run vertically and the adjacent layer runs horizontally (termed longitudinally).

Why is that important?

When used as cavity batts (built into the space in a cavity wall), any water penetrating through the outer leaf will not pass through the batt. Gravity will eventually pull the water down the cavity.

When used as loft insulation (termed 'Quilt Insulation) there is no advantage.

The other method of manufacture is random direction fibres just like those used in a man-made fibre duvet. The manufacturers claim it is more thermally efficient. Independent tests confirm it is true. However, the thermal advantage is very small, and has been carried out in laboratory conditions.

The space between each rod is filled with air. Glass / mineral wool / fibres are actually very good conductors of thermal energy. However, as they are very fine and only touch the other fibres over a very small surface area conduction is significantly reduced.

Air is trapped between the fibres. It cannot easily move, therefore the few molecules in the air will not transfer heat energy very easily, hence making it a very good insulating material. The insulation is sold in compressed rolls making it easier to transport and get through a loft hatch. The rolls must be fluffed’ up just like a duvet on a bed.

The manufacturing process described has the benefit of added strength preventing the roll of insulation falling apart. ‘Earthwool’ is the brand name used by Knauf (Formally invented and manufactured by Pilkington Brothers of St Helens). The base material is made from recycled glass bottles therefore making use of waste that would otherwise have gone to landfill.

The thermal value is very slightly less than that advertised for similar insulation, however the difference is negligible. The cost difference is noticeable.

The fibres are long, therefore create less dust when the material is handled. It is still advisable to wear a dust mask.

The heated air in the room has risen to the ceiling. As it is in contact with the plasterboard the air temperature will raise the plasterboard temperature until they are equal. The process will cool the air as the energy is transferred. The other side of the plasterboard will naturally be cooler therefore a heat flow will continue until the full thickness of the plasterboard is the same temperature as the air in the room. In reality the flow will actually be cooling the air as all of the molecules in the plasterboard use the energy.

Some of the heat will then pass to the glass fibres and they will heat up. So the glass fibres touching the ceiling will be heating up until they are the same temperature as the ceiling plasterboard. The trapped pockets of air will very slowly increase in temperature.

The temperature within the insulation will cool down gradually as less heat energy is available until the top of the insulation will be at the same temperature as the air in the loft (cold).

There is a point within the thickness of the insulation where it has lost much of the heat energy. Beyond that point putting more insulation to make it even thicker is a waste as there is not much heat energy to save. That point has been calculated at about 270mm thick.

Installing loft insulation

There are several good videos on YouTube showing how to insulate a loft. However some of the technical details are missing. For example, in a typical loft the ceiling joists will be 100mm deep (4”). The space between each joist can vary depending upon the span of the roof or room below and the size of the other roof members.

Insulation as previously mentioned is supplied in compressed rolls held in a polythene sleeve. Measure the width between the joists and using a tape measure and a marker pen put a line on the sleeve. Then repeat several times around the sleeve so that when cutting the section will be parallel. You may find the roll has been pre-marked making it easier to cut.

If an old carving or bread knife is available it makes cutting the roll much easier. (If you use your normal carving knife it will require sharpening afterwards).

Place the cut section still in its polythene sleeve roughly in the position you will be starting at. Then cut the sleeve and unroll the insulation fluffing it up when unrolled.

That's straightforward but what about all those cables and junction boxes?

Depending upon the age of the property, and more to the point when the cabling was run will make a difference. Also the quality of workmanship and materials used.

Lighting cable should be a minimum of 1mm² cross section of each wire. The old cables were typically insulated in rubber; red for live and black for neutral. There was not an earth wire within the cable. Some electricians ran a bare earth wire to specific fittings. There were different versions of outer insulation from cotton covered rubber and occasionally lead.

More recently the cabling would have PVC insulation around two cables; live red and black neutral. Between them a single wire without any insulation for the earth line. This too is very old and probably out of its useful lifespan.

If either of those types of cable are present contact a qualified and experienced electrician for advice. DO NOT leave it and insulate over it as it is dangerous. Also do not try moving the cables as the old rubber insulation is well past its useful life and will crack to expose the wiring.

Modern cabling has light grey or white outer insulation with blue and a brown insulated inner wires. The earth line is still bare wire running in between the blue and the brown wires.

Enter 'The Problem!' - DIY man (or woman) or 'Builder'

Since the 1950’s DIY has become popular. Why pay someone for something you can do yourself? The easy answer is: Would you do your own dentistry on you and your family? Why not? (Unless you are a dentist)

There are several things to consider if it is to be done safely. Cabling should run along the ceiling joists and be clipped ideally near to the top edge. Light fittings were normally pendant type secured to a length of floor board fixed at both ends to the ceiling joists. The lighting cable would run over the board and through a hole and attached to the ceiling rose. Simple, neat and safe.

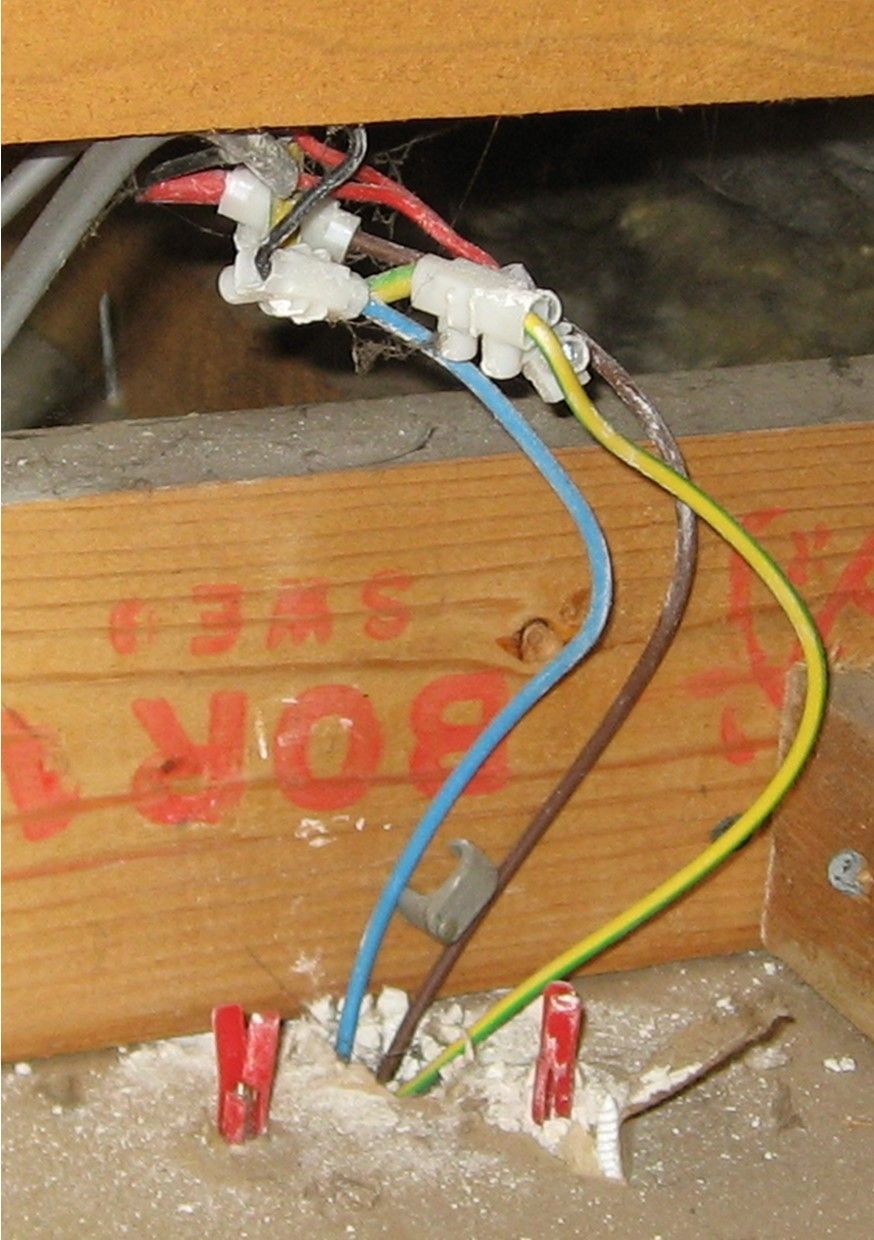

DIYer or cheapo electrician (Or so called 'Builders'). Run the cable loose anywhere and everywhere as can be seen in the photo's . Apart from a trip hazard or becoming caught up with anything put in the loft space it is all so common now.

This example was from a house survey where a 'builder' was selling the house he had 'modernised'.

- Unsheathed wires

- No junction box

- Cables unclipped

- Exposed plasterboard screw protruding through the ceiling

- No thermal insulation

The list can go on.

These photo's are from another property. The vendor was a keen DIYer. He had rewired his 1930' semi-detached house himself.

He had a 'friend' who was a qualified electrician sign the work off and issued a certificate.

None of the cable runs were clipped. Many of the cables were just bunched together.

There are other reasons / excuses: the 'electrician' doesn't want to be in the loft for very long (in the summer months it can be very hot in the loft - or very cold in the winter). The loft is full of stored items so it is difficult to work unless the loft is cleared first. Running the cables the shortest route = cheaper on materials

Does it matter? When the insulation is between the ceiling joists the cables will then be on top of the first 100mm (4"). Then placing another 170mm (7") or 200mm (8") on top of the cables sandwiching them in is going to prevent the cables naturally cooling.

Another very common issue is recessed spotlights. Very popular halogen or LED spotlights are cut into the ceiling. Halogen light bulbs produce a lot of heat. If in a ceiling of an upper floor the heat can normally dissipate within the void. However where they are installed in the ceiling of the roof void there is a problem with insulation.

If the insulation covers the lamp holder and transformer there will be a heat build up. The heat can be enough to melt the transformer casing leaving the bare wires exposed with a potential of electrocution if touched. Fire is also possible. Glass fibre will not readily burn as glass is non-combustible but it will melt and char.

Recessed light fittings should have a protective heat cup over them that enables the insulation to continue over the fitting but leaves enough space to allow the dissipation of heat produced by the light.

LED lights do not produce much heat but should be protected from the insulation with a cup over the fitting.

Bathroom / shower room extractor ducting There are several different types of ducting but they all have the same function. To enable humid air to be blown out of the building.

Insulating the loft will reduce the heat that would be lost via the ceiling, therefore any ducting will be even colder after the ceiling has been insulated. There are insulated ducting tubes available relying on the heat from the ventilated room keeping the duct warm enough to prevent condensation.

Ordinary convoluted PVC ducting will very quickly condense the water vapour and form condensation. If the duct leaks, damp patches will form on the ceiling. Ideally if possible have the ducting without any insulation below it. The heat from the room will go through the plasterboard and keep the ducting warm. Place the full amount of insulation over the top of the ducting so that it in effect is protected from the cold. Ducting should have a natural fall towards the outlet from the building so that any condensation will trickle out of the building.

The cover grill has been removed from the ceiling ducting. The owner said the extractor had been fitted 8 years ago.

There had been excessive condensation in the bathroom even though the extractor had been turned on and a 30minute over-run used.

The ducting tube had about 300mm plug of mainly towel fibres being sucked into the damp ducting caused by condensation.

The ducting cleaned and a thick layer of thermal insulation only on the top of the ducting now protects it from the cold loft. Some heat passes through the cover grill and keeps the ducting free from condensation.

The extractor fan was an in-line Vent Axia ACM 100T on maximum power. Now cleaned, the system very efficiently clears the steam from the bathroom.

An easy test to check it is functioning: twist a piece of brown wrapping paper into a small baton. Light an edge and allow to burn for a few seconds. Then blow out the flame. Hold the smoking baton of paper up to about 500mm below the extractor vent.

With it turned on the smoke should efficiently be drawn up into the ducting. (Or buy surveyor's smoke matches).

Any water storage tanks in the loft should have a close fitting lid and insulated on all sides and over the lid. If the water tank is supported over the ceiling joists there should

not

be any insulation below. It used to be said that not having insulation below the tank stopped the water from freezing. In reality the insulation around and on top of the tank should do that. Cold water storage that is on a high level platform is more susceptible to freezing therefore it should be very well insulated. There are kits available that include bags of insulation material and straps so it can be removed for maintenance. Ideally look for water tank insulation that meets 'Water Bye-Laws'.

Water pipes should have pipe insulation around them. There are different types and materials including foamed plastics, hemp bandage, and bubble wrap with a foil layer.

The foamed plastic insulation tubes are very easy to use if the pipe clips are long enough. The insulation tubes are available in 15mm, 22mm and 25mm diameter meaning that is the size pipe they fit. There are other sizes available but normally used on commercial systems. There are are also different grades that claim better insulation qualities. Are they worth paying a premium price for?

The water pipes in the loft are likely to be from the water storage tanks down to the hot water cylinder (cold feed), cold feed to the shower and bath, could be to the basin depending how the plumber ran the pipes. Those pipes will be full of water all of the time so need to be well insulated. There will be a pipe that takes the water to the tanks. It is part of the mains pipe so it will be under mains pressure and always full of water. It must be well insulated to stop it freezing.

If there is a smaller water tank in the loft it is probably the 'header' tank for the hot water system. There will be a pipe taking the water to it at mains pressure so it must be insulated. There will be another pipe that looks like a shepherds crook. That is a safety pipe from the hot water cylinder. If the boiler controls malfunction and the water temperature goes well over the maximum to boiling point the pressure will push the water up the safety pipe so it falls into the header tank. In normal circumstances the pipe should be empty above the ceiling so nothing to freeze.

Other pipes in the loft may include central heating pipes. Some installers prefer to run the pipes through the loft space to each room rather than taking up the floorboards. Very common where a room has fitted furniture or the modern sheet chipboard floor deck has been used. The pipes in the loft should already be well insulated but it is worth checking.

Pipe insulation is important. In normal winters the roof void / loft is unlikely to become cold enough to freeze water. However in the past the amount of heat entering the loft from the dwelling was enough to keep the temperatures up. Putting the extra layer of insulation will significantly reduce the heat entering the loft so pipes etc. may well freeze. Also there are freak years when the temperatures really fall below freezing and even water mains in the road can burst. So insulating the pipes is a must.

What about the pipe fittings.

A pipe may freeze and burst. Even plastic water pipes can burst. However the fittings such as valves and bends etc. are difficult to insulate. Compression fittings are bulkier than the pipes so foamed pipe insulation will not go round it. That is why some installers use the wrap around hemp bandage and cable ties. The bandage can be wrapped around a valve and then cable tied to keep it in place. The plastic bubble wrap is an alternative with duck tape to keep in in place.

Service valves such as found on the feed pipe to each water tank should be well insulated but still accessible when needed. The hemp wrap and cable ties works very well.

Why are compression fittings so vulnerable to freezing?

Most commonly made of brass they will conduct heat easily. That means any heat energy in the cold water will be lost through the pipe and even more easily through the fitting. So the area around the fitting will freeze quicker. Moving water freezes at a lower temperature.

Problem

A family went on a winter holiday for two weeks skiing. They turn the gas off. Why heat the home if they are not going to be there? They arrived back from holiday to find their home completely gutted. Ceilings hanging down, carpets, sofa and everywhere soaked. They went upstairs to find exactly the same thing, everywhere soaked.

The neighbour pops round to say they had heard noises and knew they were away. Probably the ceilings falling down. The emergency services turned off the water at the road stopcock. The bill the insurance company paid out was in excess of £47k. The family had to live at a local hotel whilst the house was dried out and completely refitted. What was the cause? An un-insulated cold water pipe valve in the loft.

The water had been still for a long period and the weather had been unusually cold. The water in the pipe had frozen and expanded enough to push the copper pipe out from the olive. (A small ring of metal that forms the water seal in a compression fitting). The mains water pressure was enough to then to push the ice plug out and continue to gush into the property.

Yes it is important to insulate all the valves and elbows properly.

An easy and efficient way to insulate awkward fittings is to place a few handfuls of insulation material into a polythene bag and wrap it around the fitting. Using either duct tape or long cable ties secure the bag in place. (Cable ties make it much easier if the fitting need to be accessed. Cut the ties - do the job - put new ties back.